What is deep hole drilling?

Deep Hole Drilling Guide

Mastering Deep Hole Drilling Techniques to Enhance Precision and Efficiency

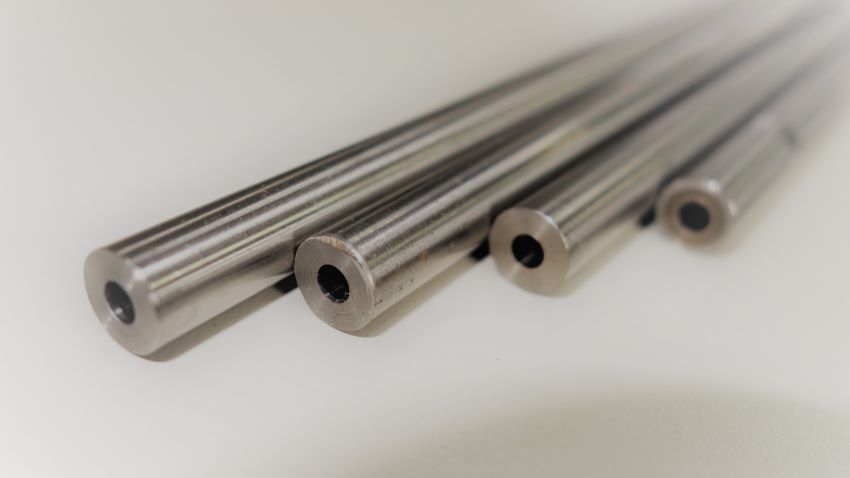

In machining, when the hole depth exceeds 10 times the hole diameter (Deep Hole = Depth / Diameter > 10), specialized deep hole drilling techniques are required to ensure precision and stability.

Key Techniques for High-Quality Deep Hole Drilling

Choosing the Right Drilling Method

- Gun Drilling – Ideal for small-diameter, high-precision applications.

- BTA Drilling – Suitable for large-diameter and high-efficiency drilling.

Optimizing Cutting Conditions

- Set appropriate spindle speed and feed rate to prevent overheating.

- Use high-pressure coolant to improve chip evacuation.

How to Prevent Scratches When Retracting

Controlling Retraction Speed

- Use slow and uniform retraction to reduce tool-wall contact pressure.

- Implement segmented retraction to ensure chip evacuation.

Enhancing Cooling and Lubrication

- Use high-pressure coolant to flush away chips.

- Select low-viscosity cutting oil suitable for the material.

Maintaining Machine and Process Stability

- Ensure machine rigidity to minimize vibrations.

- Keep the hole clean by using air or coolant flushing.

Precision Control for Higher Quality

By optimizing retraction speed, improving cooling, and ensuring machine stability, deep hole drilling can significantly reduce surface scratches and enhance hole quality.

#deep hole machining #gun drilling #gundrill #GunDrill #BTA drilling #precision machining #CNC deep hole machining #BTA #deephole #drill